CUTTING

Metallographic cutting

In metallography, cutting (or metallographic cutting) is the first step in preparing a sample for its analysis. The quality of the cut is essential since a well-executed cut will preserve the entire structure and preserve the initial properties of the sample. It also allows to save time and use of consumables.

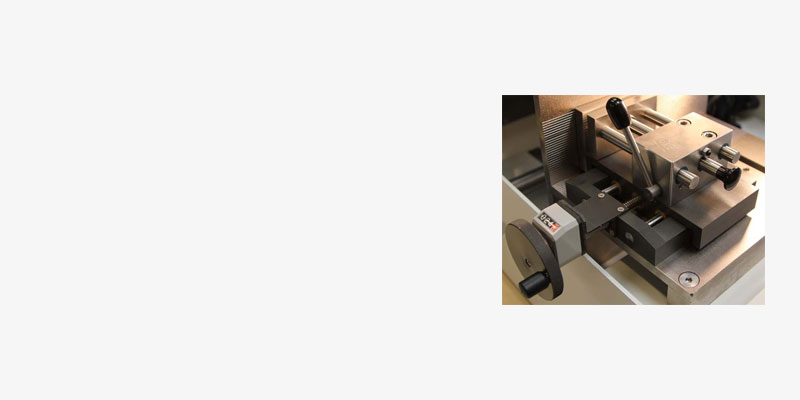

CUTTING MACHINES

Depending on the size of the sample and the type of cut to be made, PRESI offers several types of cutting machines: micro-cutting machine, manual or automatic cutting machines, etc. Powerful, easy to use and with increased cutting capacities, our cutting machines cover all needs with the guarantee of fast, precise and quality cutting.

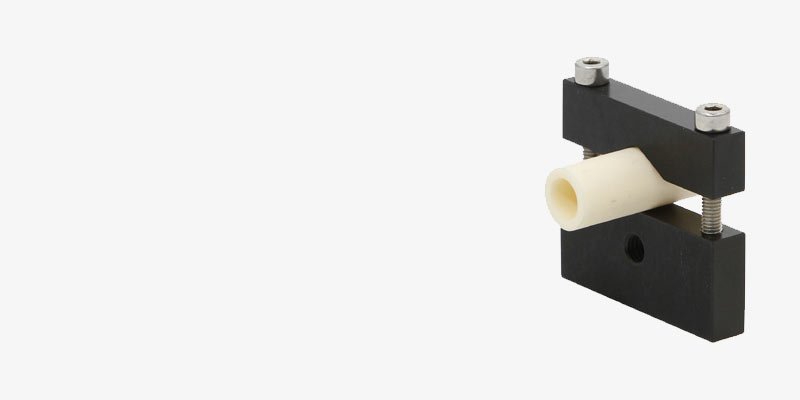

CUTTING ACCESSORIES

Whatever the type of material or the size of the sample to be cut, the sample must be perfectly stable, that is to say, well oriented and well-fixed so that the cut is optimal. To facilitate the handling of samples and to boost cut’s replication for greater productivity, PRESI offers a wide choice of cutting accessories: vices, clamping systems, specimen holders, cutting tables, etc.

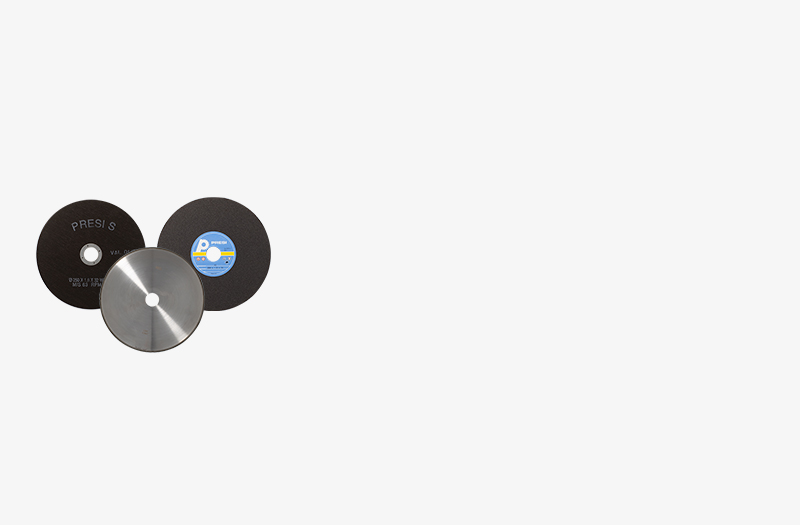

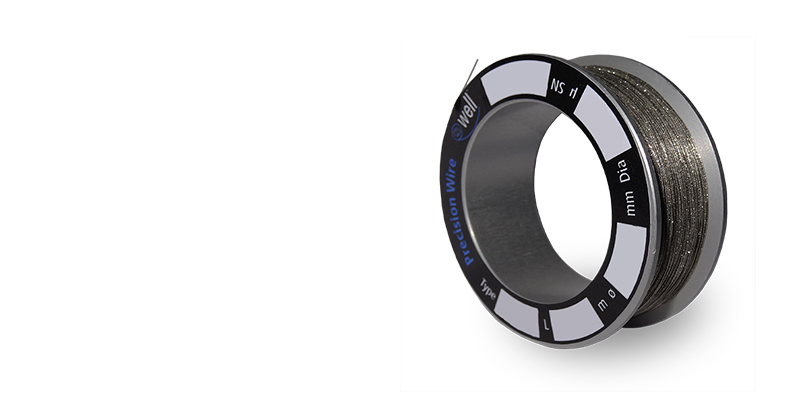

CUTTING CONSUMABLES

Choosing the right machine and the right cutting accessories are not enough. The use of appropriate and relevant consumables is also essential. With resinoid cut-off wheels or diamond and CBN cut-off wheels, PRESI has a wide range of very high quality suitable for cutting any type of material. Our cutting consumables preserve the sample structure so that it does not overheat and deform while ensuring maximum cut-off wheels life.