PRESI GUIDES

In order to choose your consumables, follow the Guide !

CUTTING

Resinoid cut-off wheels are made of a mixture of resin and abrasive powder and are suitable for cutting most materials. The nature of the abrasive and the hardness of the resin used are fundamental elements to ensure a perfect cut. The harder the material is, the softer the cut-off wheel must be. Cut-off wheels made of abrasive Al2O3 (alumina) are intended for cutting ferrous materials. Cut-off wheels made of abrasive Sic (silicon carbide) are intended for cutting non-ferrous materials.

Metallic cut off-wheels and CBN cutting discs only cut hard materials. There are two types of abrasives: diamond and boron nitride (CBN). Resin bonds give better surface conditions than metal bonds. Metal bonds have a longer life than resin bonds.

MOUNTING

Cold mounting or hot mounting? In order to cover all needs, PRESI offers hot mounting machines and cold mounting machines. In order to preserve the structure and integrity of the sample to be mounted and to achieve the desired results, it is necessary to determine which mounting technique is most appropriate.

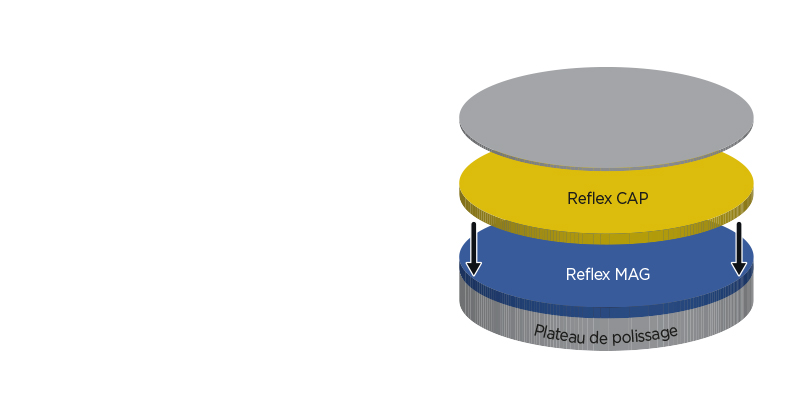

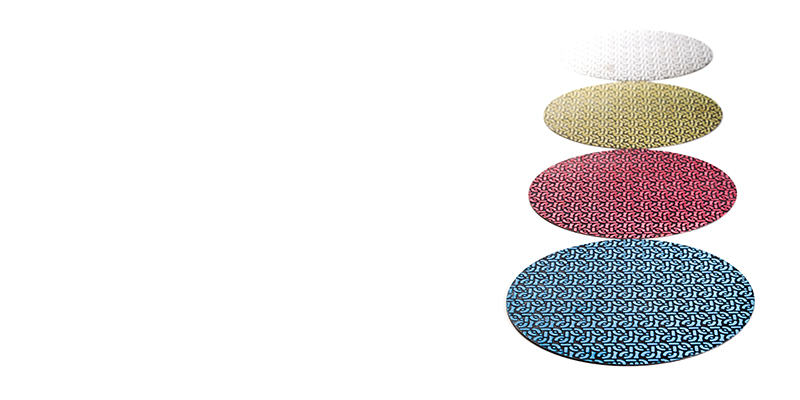

POLISHING

Use the 3 guides below to choose the best grinding and polishing consumables fitted to your issues.

HARDNESS

Type of indenter, range of loads, number of positions of the turret … are all criteria to consider when choosing a micro or macro-hardness tester. Discover below at a glance our guide to find the right equipment for your needs.