Automatic Hardness tester HZ30-4

Automatic hardness tester. Optical quality, reliability and precision. The HZ30-4 hardness tester is instantly recognizable. 100% made in France, its original design along with its robustness and highly technical capacities make it an essential work tool. High rigidity of the chassis for a perfect load application.

- Load range : 100gf-30kgf

- Turret: : up to 4 lenses, 2 indenters, 1 touch sensor

- Indenter type : Vickers or Knoop

- 1 load cell

- Nikon objectives for a magnification up to 2000x

- Ergonomic joystick with customizable sensitivity

- Silent operation

- Emajor vertical extension: allows a large work space

- 2 LED lighting system: for micro and macroscopy use

- Standard or marble motorized stage

Key word: hardness

Mecatome T215

Robust and compact, the MECATOME T215 is an automatic micro-cutting machine. Its three programmable motorized axes make it a machine that adapts to all situations.

The MECATOME T215 offers numerous work parameters that allow to optimize the cutting of the most complex parts.

Accessories and options:

- Quick clamping vice left side for MECATOME T215 (ref. 51466)

- Quick clamping vice right side for MECATOME T215 (ref. 51465)

- Quick clamping vice for long sample for MECATOME T215 (ref. 51469)

- Sample chucks (to use only with a transversal table) for MECATOME T215 (ref. 51410)

- V shaped sample chuck for MECATOME T215 (ref. 51715)

- Vice chuck for longitudinal cuts for MECATOME T215 (ref. 51717)

- Orientable chuck for MECATOME T215 (ref. 51156) to be used with aluminium plates (ref. 51162 et 51163)

- Irregular shaped sample chuck for MECATOME T215 (ref. 51716)

- Chuck for small samples for MECATOME T215 (vice type) (ref. 51713)

- Chuck for cylindrical sample for MECATOME T215 (ref. 51714)

- Base cabinet for manual cutting machine pour MECATOME T215 (large model) (ref. 51470)

- Kopal holding (ref. 50616)

- Box of Kopal holders (ref. 50613)

- Option:Transversal table with motorized movement for MECATOME T215 (ref. 51461)

- Option: 25L recirculating tank for MECATOME T215 (ref. 51462)

- Option: Positioning laser for MECATOME T215 (ref. 51463)

- Option: Suction & extraction (ref. 51464)

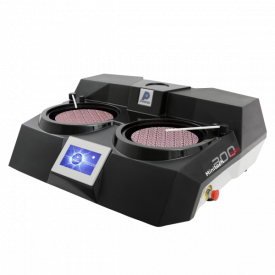

MINITECH 300 DP1

The MINITECH 300 DP1 is a manual polishing machine equipped with two platens Ø 250 to 300 mm and one motor. It has the most advanced technologies. Thanks to a motor power from 750W to 1500W, the entire PRESI experience is condensed in this most complete range on the market. User-friendly, reliable and robust, MINITECH provides a simple answer to all needs. With its affirmed style and edged lines, this new range is distinguished by its new design with an easily recognizable sleek and refined carbon look.

Fully Automatic Hardness tester HZ50-4

Fully automatic hardness tester. Optical quality, reliability and precision. The HZ50-4 hardness tester is instantly recognizable. 100% made in France, its original design along with its robustness and highly technical capacities make it an essential work tool.

High rigidity of the chassis for a perfect load application.

- Load range : 5gf-65kgf

- Turret: : 4 lenses, 2 indenters, 1 touch sensor

- Indenter type : Vickers AND Knoop

- 2 load cells

- Nikon objectives for a magnification up to 2000x

- Ergonomic joystick with customizable sensitivity

- Silent operation

- Emajor vertical extension: allows a large work space

- 2 LED lighting system: for micro and macroscopy use

- Marble motorized stage

Key word: hardness

MECATOME T335

Powerful and precise, the MECATOME T335 is an automatic cut-off machine on its longitudinal axis and manual on its vertical axis. Its rotation speeds range from 1000 to 6000 RPM, allowing the use of metal discs as resinoids.

The MECATOME T335 offers the best of both worlds, with the possibility of making regulated or impulse cuts while retaining the ease of manual cutting.

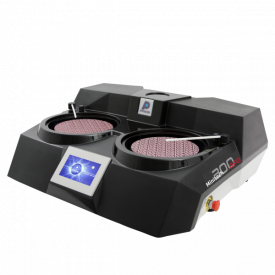

MINITECH 300 DP2

The MINITECH 300 DP2 is a manual polishing machine equipped with two platens Ø 250 to 300 mm and two motors. It has the most advanced technologies. Thanks to a motor power from 750W to 1500W, the entire PRESI experience is condensed in this most complete range on the market. User-friendly, reliable and robust, MINITECH provides a simple answer to all needs. With its affirmed style and edged lines, this new range is distinguished by its new design with an easily recognizable sleek and refined carbon look.

Mecapress 4

Mecapress 4: latest generation of pneumatic hot mounting press!

Versatile and powerful, it enables high-quality and suitable mountings thanks to automatic

mould recognition.

Cycle times are optimized with the latest generation of moulds.

Mecapress 5

MECAPRESS 5 is a modular hydraulic hot mounting press.

Versatile and powerful, it enables the productionof high-quality, customized mounts thanks to automatic mould recognition.

MECAPRESS 5 can accommodate up to two additional mounting modules, allowing a large number of samples to be processed daily.

Mounting time is significantly reduced with the latest-generation molds.

MECATECH 250 SPI

MECATECH 250 SPI is equipped with a Ø 200 to 250 mm platen / 4 pistons / individual pressure. It has the most advanced technologies. The MECATECH range allows both manual and automatic use. Thanks to a motor power from 750W to 1500W, the entire PRESI experience is condensed in this most complete range on the market. Whatever the size or the number of samples, MECATECH guarantees an optimal polishing. With its affirmed style and edged lines, this new range is distinguished by its new design with an easily recognizable sleek and refined carbon look.

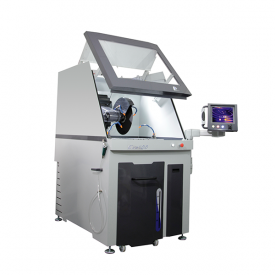

Mecatome T345

Powerful and precise, the MECATOME T345 is an automatic cutting machine.

Its rotation speeds ranging from 300 to 6000 RPM allow the use of diamond discs as well as resinoids.

Its three programmable motorized axes make it a machine that adapts to all situations.

The MECATOME T345 offers numerous cutting modes which optimize the cutting of the most complex parts.

MICROTECH MX3

The Vickers MX3 hardness tester with manual turret offers a complete solution in order to meet the needs of quality laboratories, as well as on-line controls.

• Manual turret up to 6 positions.

• Vickers and Knoop hardness.

• Automatic load application.

• High-rigidity frame.

EVO 400

Large size cutting machine. Evo 400 Ref. 50400 / Evo 400+ Ref. 50430

The EVO 400 is a very spacious, large capacity machine. The height of the space under the grinding wheel measures 190mm. Its tables can bear the weight of parts over 200kg. This powerful machine, adapted for workshop use, combines ease of use with sturdiness. It has three cutting modes: assisted, automatic, programmable (ensures cut repeatability). Its ergonomic design, with a motorised hood and multilingual, coloured, touch screen simplifies the user-machine interface. Optional Extras:

• Positioning Laser.

• Manual transverse movement table (X axis) to assist with lateral adjustment of the simple, and enable parallel sectioning.

• Manual longitudinal movement table (Y axis) to increase cut capacity.