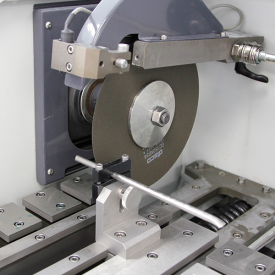

Sample chucks (to use only with a transversal table)

Accessory for MECATOME T215 (ref. 51460)

Chuck for cylindrical sample (up to 32mm)

Accessory for MECATOME T215 (ref. 51460)

Orientable chuck

Accessory for METACOME T215 (ref. 51460)

V shaped sample chuck

Accessory for METACOME T215 (ref. 51460)

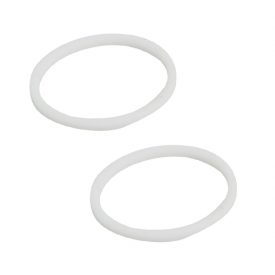

Reduction ring 25,4 /22 mm

Pack of 20. Reduction rings allow to adapt the interior diameter of the cut-off wheel with the machine arbor.

Boron nitride carbide cut-off wheels Type CBN ⌀ 300 x 1,2 x 32 mm

Delivered with a dressing stick. Resin bond. High boron nitride concentration disk for cutting hard ferrous materials, cast iron and treated, high-speed and hard steel.

Boron nitride carbide cut-off wheels Type CBN ⌀ 200 x 0,9 x 32 mm

Delivered with a dressing stick. Resin bond. High boron nitride concentration disk for cutting hard ferrous materials, cast iron and treated, high-speed and hard steel.

Boron nitride carbide cut-off wheels Type CBN ⌀ 150 x 0,6 x 12,7 mm

Delivered with a dressing stick. Resin bond. High boron nitride concentration disk for cutting hard ferrous materials, cast iron and treated, high-speed and hard steel.

Boron nitride carbide cut-off wheels Type CBN ⌀ 75 x 0,5 x 12,7 mm

Delivered with a dressing stick. Resin bond. High boron nitride concentration disk for cutting hard ferrous materials, cast iron and treated, high-speed and hard steel.

Diamond cut-off wheels Type LR ⌀ 250 x 1,2 x 32 mm

Delivered with a dressing stick. Resin bond. High concentration disc, advised when you want the best cutting quality. To cut hard and fragile materials, composites, plasma deposit, ceramics, electronic components.

Diamond cut-off wheels Type LR ⌀ 175 x 0,7 x 12,7 mm

Delivered with a dressing stick. Resin bond. High concentration disc, advised when you want the best cutting quality. To cut hard and fragile materials, composites, plasma deposit, ceramics, electronic components.